Tungsten Carbide Strips Cutter ad Woodworking

Descriptio

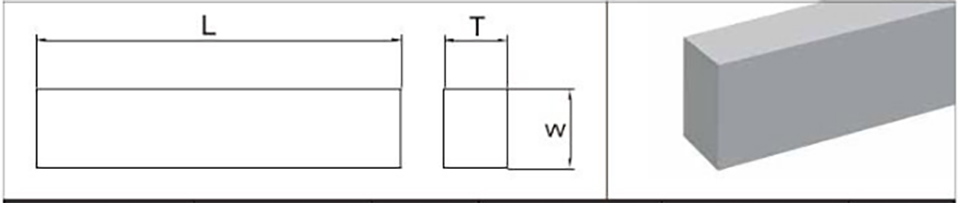

Tungsten carbide plana vectes sunt maxime factum ex Wolfram carbide et Cobalt pulveris per pulveris metallicy modi. Pelagus productio processus Tungsten Carbide Bar Stock est pulveris milling, pila milling, urgeat et peccare. Nam diversis usus, in contentus de WC et CO in Tungsten Carbide Quadratus Bar est idem. Solidum carbide rectangulum talea est maxime solebat processus griseo mittetur ferrum, non-ferrea metallum materiae, frigida mittebant ferrum, obduratum ferrum, PCB, fregit in clients, talea vel officina a filum in clients, officinas vel officina a filum cut, molere vel officina per filum in clients, aut officina, solidatoris.

Applications

I. ad gerunt-repugnans instrumenta. Ut woodworking industria cultris, plastic opprimens cultros, etc.

II. Solebant facere summus temperatus resistant partes, gerunt, repugnant partes, anti-protegens partium. Ut dux rail de machina instrumentum, anti-furtum Reinforcement laminam de atm machina, etc.

III. Usus ad induendum, repugnans partes in Flexilis et plastic industria.

IV. Usus ad facere fingit.

V. De materia proprietatibus cementatae carbide laminis pro diversis proposita non consistent, et opportunitate materiam cemented carbide laminis debet electus secundum usum cum usura.

Cubits

Communi ut infra:

| Crassities | Latitudo | Longitudo | Crassities | Latitudo | Longitudo | ||||

| mm | mm Tolerantia | mm | mm Tolerantia | + 1.5mm Tolerantia | mm | mm Tolerantia | mm | mm Tolerantia | + 1.5mm Tolerantia |

| 2 | + 0,3 / 0,1 | 3 | + 0,4 / + 0,2 | CCCX | 3 | + 0,3 / 0,1 | 15 | + 0,6 / + 0,2 | CCCX |

| 2 | + 0,3 / 0,1 | 4 | + 0,4 / + 0,2 | CCCX | 3 | + 0,3 / 0,1 | 16 | + 0,6 / + 0,2 | CCCX |

| 2 | + 0,3 / 0,1 | 5 | + 0,4 / + 0,2 | CCCX | 3 | + 0,3 / 0,1 | 18 | + 0,6 / + 0,2 | CCCX |

| 2 | + 0,3 / 0,1 | 6 | + 0,4 / + 0,2 | CCCX | 3 | + 0,3 / 0,1 | 20 | + 0,6 / + 0,2 | CCCX |

| 2 | + 0,3 / 0,1 | 8 | + 0,4 / + 0,2 | CCCX | 3 | + 0,3 / 0,1 | 22 | + 0,6 / + 0,2 | CCCX |

| 2 | + 0,3 / 0,1 | 10 | + 0,4 / + 0,2 | CCCX | 3 | + 0,3 / 0,1 | 25 | + 0,6 / + 0,2 | CCCX |

| 2 | + 0,3 / 0,1 | 12 | + 0,4 / + 0,2 | CCCX | 3 | + 0,3 / 0,1 | 28 | + 0,6 / + 0,2 | CCCX |

| 2 | + 0,3 / 0,1 | 14 | + 0,4 / + 0,2 | CCCX | 3 | + 0,3 / 0,1 | 31 | + 0,6 / + 0,2 | CCCX |

| 2 | + 0,3 / 0,1 | 15 | + 0,4 / + 0,2 | CCCX | 4 | + 0,3 / 0,1 | 5 | + 0,6 / + 0,2 | CCCX |

| 2 | + 0,3 / 0,1 | 16 | + 0,4 / + 0,2 | CCCX | 4 | + 0,3 / 0,1 | 6 | + 0,6 / + 0,2 | CCCX |

| 2 | + 0,3 / 0,1 | 18 | + 0,4 / + 0,2 | CCCX | 4 | + 0,3 / 0,1 | 8 | + 0,6 / + 0,2 | CCCX |

| 2 | + 0,3 / 0,1 | 19 | + 0,4 / + 0,2 | CCCX | 4 | + 0,3 / 0,1 | 10 | + 0,6 / + 0,2 | CCCX |

| 3 | + 0,3 / 0,1 | 3 | + 0,4 / + 0,2 | CCCX | 4 | + 0,3 / 0,1 | 12 | + 0,6 / + 0,2 | CCCX |

| 3 | + 0,3 / 0,1 | 4 | + 0,4 / + 0,2 | CCCX | 4 | + 0,3 / 0,1 | 13 | + 0,6 / + 0,2 | CCCX |

| 3 | + 0,3 / 0,1 | 5 | + 0,4 / + 0,2 | CCCX | 4 | + 0,3 / 0,1 | 15 | + 0,6 / + 0,2 | CCCX |

| 3 | + 0,3 / 0,1 | 6 | + 0,4 / + 0,2 | CCCX | 4 | + 0,3 / 0,1 | 16 | + 0,6 / + 0,2 | CCCX |

| 3 | + 0,3 / 0,1 | 8 | + 0,4 / + 0,2 | CCCX | 4 | + 0,3 / 0,1 | 18 | + 0,6 / + 0,2 | CCCX |

| 3 | + 0,3 / 0,1 | 9 | + 0,4 / + 0,2 | CCCX | 4 | + 0,3 / 0,1 | 20 | + 0,6 / + 0,2 | CCCX |

| 3 | + 0,3 / 0,1 | 10 | + 0,4 / + 0,2 | CCCX | 4 | + 0,3 / 0,1 | 22 | + 0,6 / + 0,2 | CCCX |

| 3 | + 0,3 / 0,1 | 11 | + 0,4 / + 0,2 | CCCX | 4 | + 0,3 / 0,1 | 25 | + 0,6 / + 0,2 | CCCX |

| 3 | + 0,3 / 0,1 | 12 | + 0,4 / + 0,2 | CCCX | 4 | + 0,3 / 0,1 | 30 | + 0,6 / + 0,2 | CCCX |

| 3 | + 0,3 / 0,1 | 13 | + 0,4 / + 0,2 | CCCX | |||||

Commoda

Nostra Tungsten Carbide habena scriptor commoda:

I. calor stabilitatem.

II. Anti-deformatio in altum temperatus.

III. Fine scelerisque concursorum.

IV. Excelsus scelerisque.

V. Optimum oxidation imperium facultatem.

VI. Fortis anti-corrosio in altum temperatus.

VII. Bonum corrosio resistentia a eget.

VIII. High-circumdatio pluma.

IX. Longum usus vita.

Sarcina

Package of cemented carbide vectes:

Si vos have ullus questions, grata ad contact us in aliquando!

Productio apparatu

Infectum molere

SPRY siccatio

Proripio

TPA Press

Semi-torcular

Hip Sinctering

Dispensando apparatu

EXERCITATIO

Filum secans

Vertical stridor

Universal molere

Planum stridor

CNC Milling Machina

Inspectionem instrumentum

Duritia meter

Planimeter

Quadratica elementum mensura

Cobalt Magnetic

Metallographic Microscope